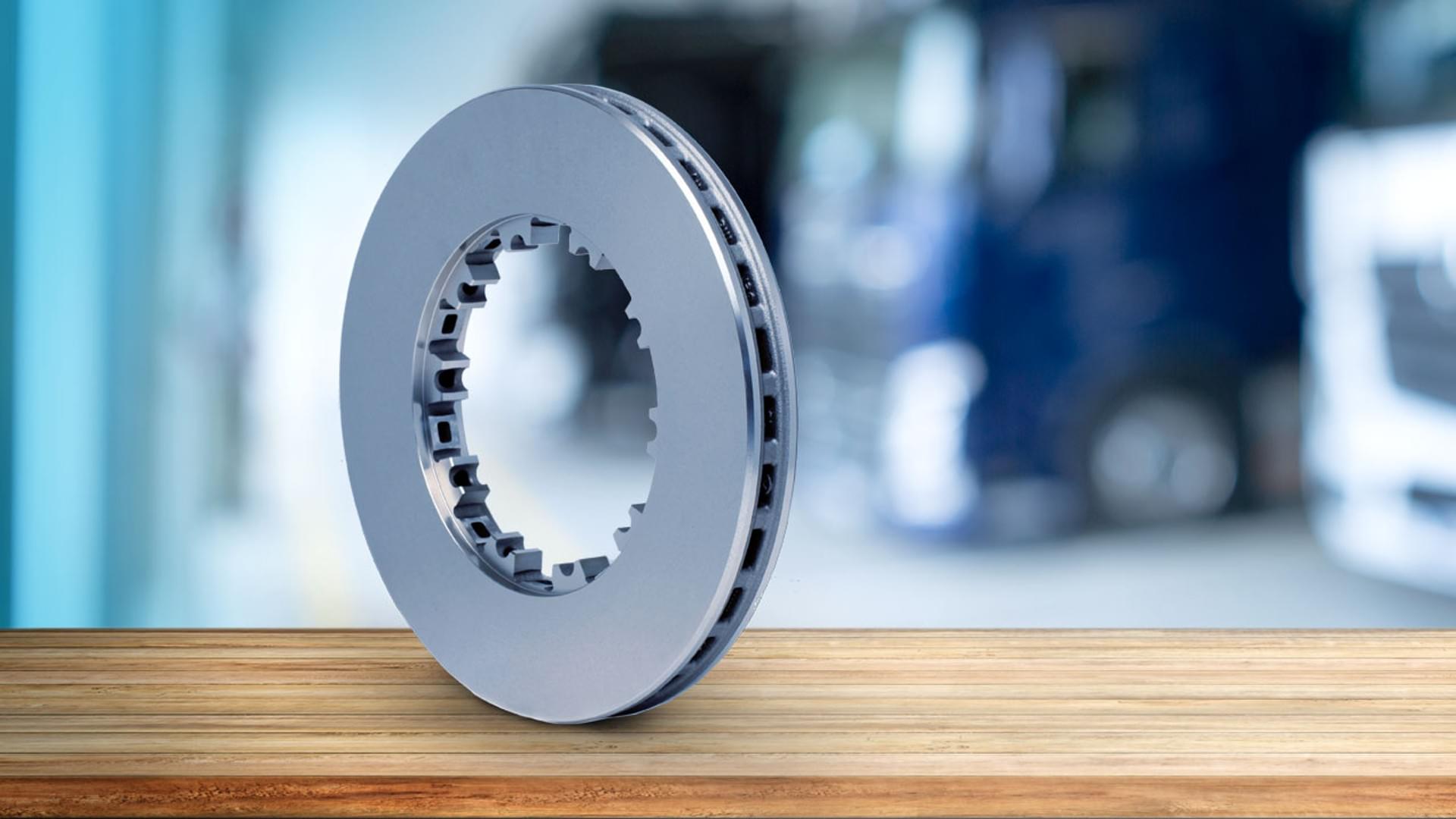

More than 50 million Knorr-Bremse disc brakes sold worldwide and more than 8 million commercial vehicles driving efficiently and safely on roads all over Europe thanks to our products – for this, we’d like to say THANK YOU. For over 30 years, you’ve placed your trust in the quality and performance of our OE parts. And we intend to make certain it stays that way. We want to ensure you remain as safe as possible when driving thanks to the extensively tested and proven in practice products, among others our Knorr-Bremse brake pads.

OE quality

You can’t actually see what’s inside a brake pad. Our pads have been developed to withstand the stringent demands of the corresponding model series, with all their relevant specifications. Because we know this, we’ve optimised the friction material we use for braking efficiency and durability. The results are longer service life, lower total cost of ownership (TCO) and maximum customer satisfaction.

Cheaper, safer travel

It’s important to keep residual brake drag torque under control as a way of extending the lifetime of brake discs and pads. This torque is consistently minimised in our systems. But what does that mean? There’s less contact between the pads and the disc in comparison with the products of our competitors. This reduces diesel consumption on a daily basis and protects the wheel bearings. That’s because excessive residual brake drag torque causes heat to build up in the discs and hence the wheel bearings as well, resulting in increased wear. This results in avoidable repairs, downtime and costs. That’s why it pays to opt for the quality and performance of OE brake pads.

Tried and tested – on the test bench, in the field

Our brakes and pads are always proving their worth on roads all over the world. We also subject them to constant testing on our test benches so that we can continue optimising them. As the experienced developer of high quality OE products, we invest a lot of effort in making our wear parts even better – and this includes our brake pads. Along the way, we’ve enhanced the performance and convenience of our brake pads by means of innovations such as partially integrated tappets, tilted edges and bed-in coatings. When it comes to tough everyday use, this ultimately means less vibration when braking, less wear and improved brake performance.

*Based on our global share of the market for air disc brake products for commercial vehicles

Benefits of Knorr-Bremse brake pads

- Developed in line with OE specifications and test standards

- Meet the stringent demands of model series specifications

- Are extensively tested and performance has been verified in practice

- Continuous improvements

- Maximum performance thanks to optimised friction material

- Minimised wear due to lowest residual brake drag torque

- Bearing wear protection thanks to low heat input

- Long service life, low TCO

- Outstanding reliability

- Innovative ProTecS® brake pad spring system

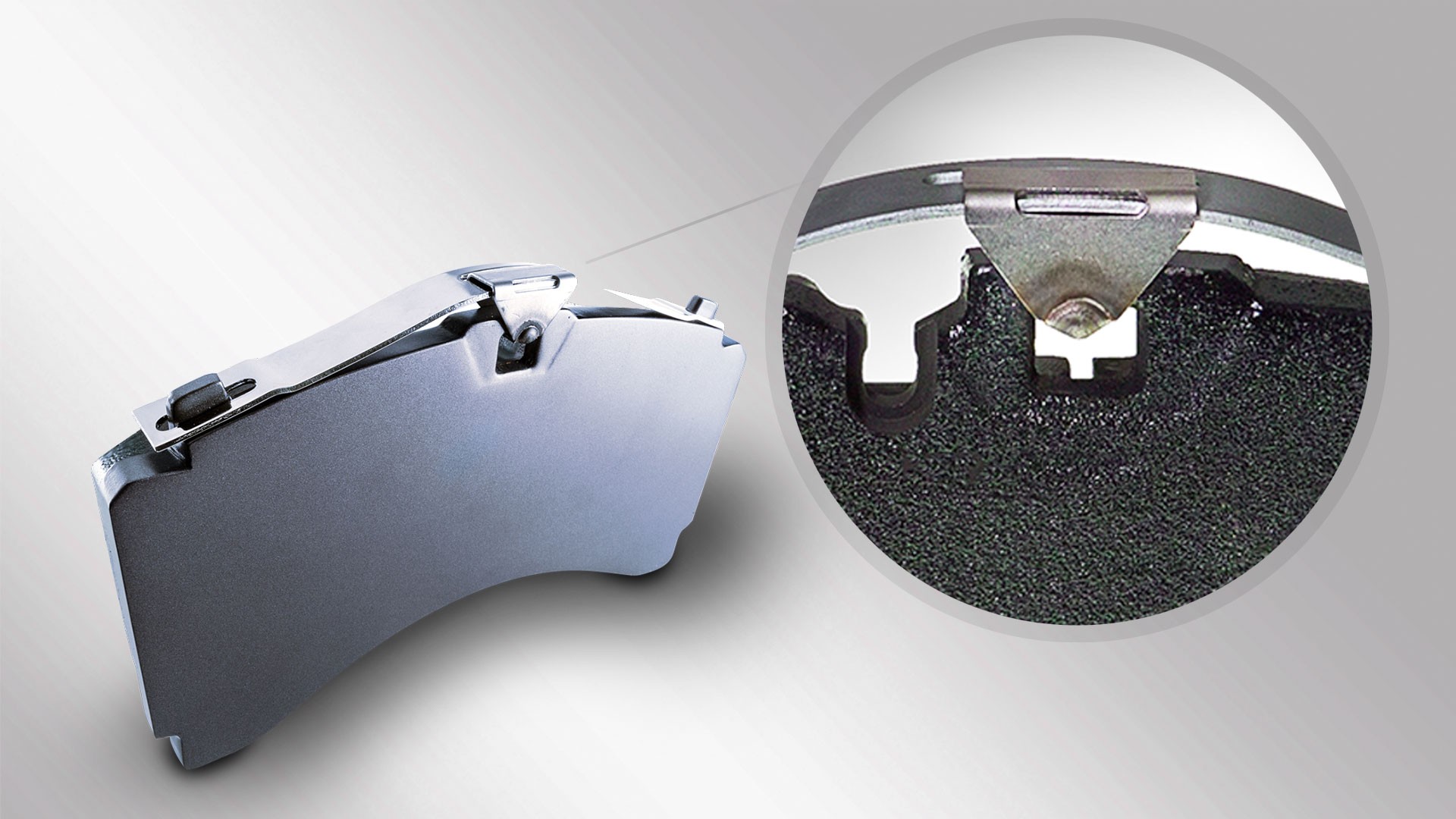

A characteristic OE: the ProTecS® brake pad spring system

ProTecS® connects the brake pads back plate to the pad holder spring by means of a welded hood, eliminating virtually all errors during installation. The benefits are:

- Precise alignment of the spring force ensuring optimum brake pad guidance

- Longer brake pad life expectancy, particularly on rough roads

- Less wear due to dirt thanks to the welded spring holder, which acts like a slider

- Minimised noise emissions thanks to the weight-optimised cast back plate (less inertia, no radial acceleration of the brake pad)

- Brake pad deformation is significantly reduced

You can work out exactly which Knorr-Bremse brake pad kit you need with just three clicks.

If the pad kit comes equipped with ProTecS®, this is indicated to the right of the product number.

Brake Parts Finder

Want to know more about our wheel end portfolio? Just one click will take you to our download area.

Download brochure