More than 50 million Knorr-Bremse disc brakes sold – for this, THANK YOU. And we continue with our mission to make your driving safe thanks to the extensively tested and proven in practice products, among others our Knorr-Bremse brake discs. What’s more, our solutions offer you numerous other benefits such as optimised friction pairing and our Splined Disc® -brake disc designed especially for heavy commercial vehicles with easy installation and durability.

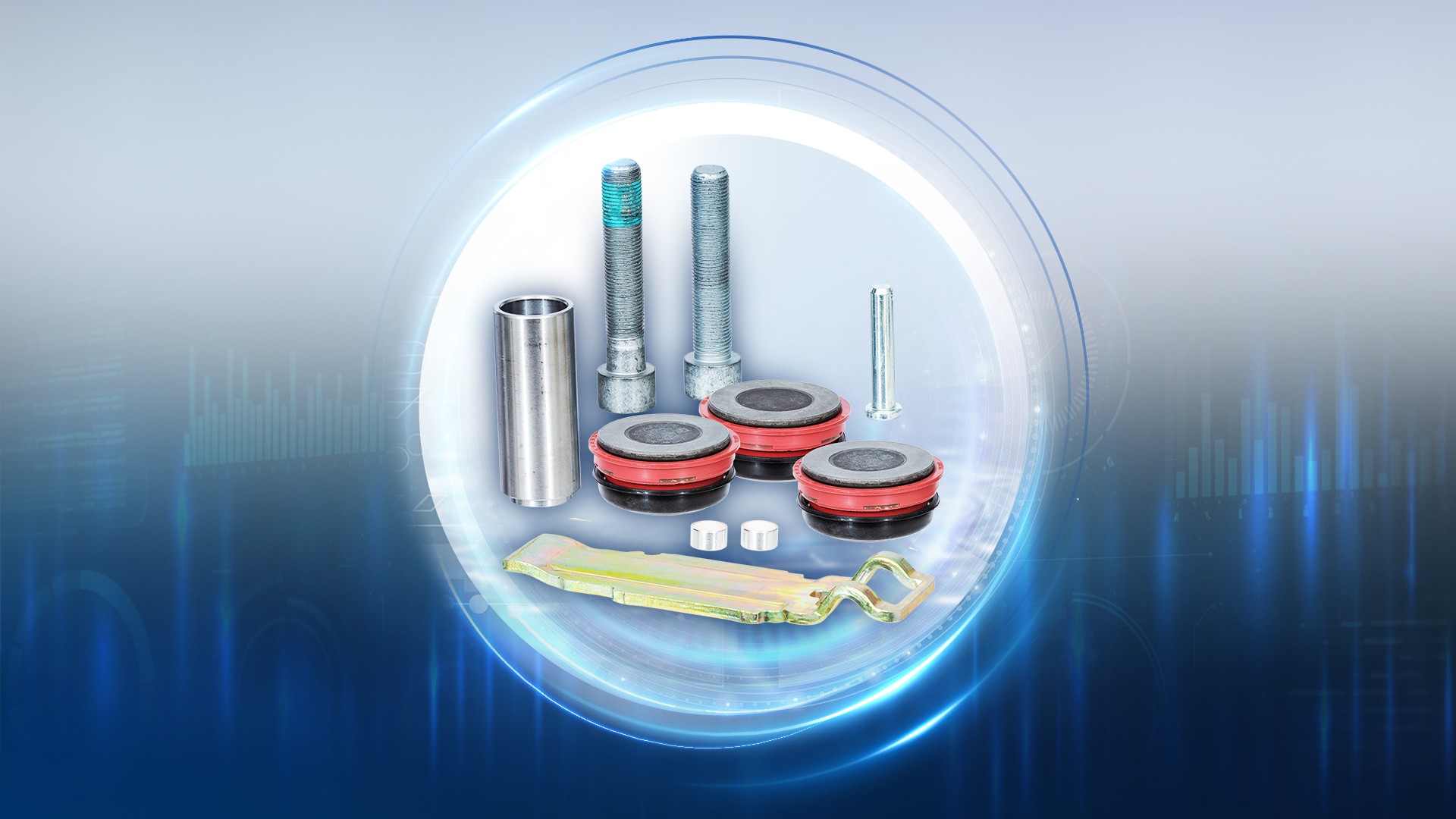

Part of a great team

Ours are not just any old brake discs, but well-engineered, thoroughly tested, OE quality brake discs that have been tried and tested on the roads; in other words, brake discs that you can rely on. All parts of our brake systems are matched to OE specifications, right down to the last detail. The overall concept pays off because, for example, disc and pad materials are precisely matched. This means vibration and wear are minimised, while heat management and brake performance are optimised. This is cost-effective, ensuring reliability and ultimately allowing you to work without stress.

It’s all about the friction pairing

Friction pairing is an aspect that we’re constantly working on. There is always some slight contact between pad and disc even when the brakes aren’t applied. This is known as residual brake drag torque. However, residual brake drag torque can be minimised. A lot of parameters have to be taken into account during development and continuous improvement to achieve this, and a number of adjustments need to be made. This is precisely what our engineers and developers do, all over the world. The result is significantly less heat generation, which reduces the stress on the system in general and minimizes wear. Vehicles also use a lot less diesel, which helps to save money, improve the TCO (total cost of ownership) and enhance sustainability.

OE quality is and will always be OE quality

A lot of effort goes into developing OE disc brakes for model series. Lots of specifications and test standards have to be taken into account, ultimately leading to that special “original equipment quality” that imitators can barely hope to achieve. And this is a quality that is synonymous with safety, reliability, durability and cost optimisation. Ultimately, it is our joint aim to get commercial vehicles back on the road – with a clear conscience.

The Splined Disc® brake - one of the world’s best brake discs

Knorr-Bremse has developed the Splined Disc® specifically to cope with the toughest jobs on the road. This special design optimises thermal insulation between the brake disc and the wheel hub. Spacers are used to reduce the transfer of heat flow into the hub bearing. Splined Discs® reduce uneven pad wear as there’s virtually no shielding effect. Spring elements and the symmetrical design facilitate thermal expansion in the axial direction.

This ensures one of the world’s best brake discs! Besides the lower weight per wheel compared to conventional solutions and increased thermal crack resistance, wear on the brake discs and pads is also reduced.

*Based on our global share of the market for air disc brake products for commercial vehicles

Benefits of Knorr-Bremse brake discs

- Demanding OE quality requirements are met

- Intensively tested, proven time after time

- Coordinated in detail to the overall brake system

- Optimised disc/pad friction pairing

- Diesel savings, greater sustainability

- Minimised vibration and wear

- Optimised heat management and brake performance

- Long service life, low TCO (total cost of ownership)

- Economical solutions for all maintenance and servicing requirements

- The Splined Disc® for extreme loads

- The comprehensive portfolio of all Knorr-Bremse brake discs

You can work out exactly which Knorr-Bremse brake disc you need with just three clicks.

Brake Parts Finder

Want to know more about our wheel end portfolio? Just one click will take you to our download area.

Download brochure